In this issue:

How Laser Alignment is Changing Manufacturing, Construction & Security

Ever since their development in 1960, lasers have been used in thousands of applications within science, medicine and industry. It would be hard to come across a modern electronic device that didn't use lasers either in its manufacturing or as a direct component. For example, laser-enabled micro material processing is used to make screens for smartphones, tablets and TVs, while optical computer mice use lasers and photodiodes to detect movement on a surface. In this month's feature, we take a look at how lasers are used for alignment in various industries.

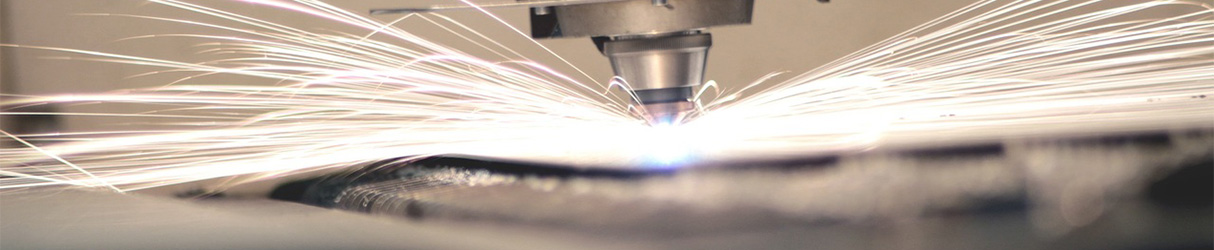

For most factory-based manufacturing facilities, laser-enabled alignment is found to be the best tool for shaft, pump, motor and pulley alignments. The usage of lasers reduces operating costs, lowers power consumption and maximizes life expectancy of bearings, seals etc. as it reduces the time taken to achieve accurate positioning, and lessens unexpected machine downtimes occurring due to misalignment. Lasers may be adapted to be used for many similar applications, like machining center alignment, ensuring the flatness of a surface, laser leveling and injection molding machine alignment.

Lasers are also used as guide-lights for positioning work pieces, equipment and tools. Laser mounted on saws can project a straight line on wood that allows precise sawing and cutting operations like board sorting, edging and planer infeed. Metal industry applications include fast and precise alignment for large work pieces like steel and aluminum plates. At a low power level, lasers may also be mounted on fabric and leather cutting devices for projecting cut-lines.

Building and maintenance of jigs and fixtures is easily accomplished by means of laser mounted trackers. This allows precise alignment of critical parts like holes, edges and pins. Laser light may also be used for projecting a shape and determining positions of different components in the absence of a physical jig or fixture. Lasers can be used for safety in crane and forklift applications, when a heavy structure must be moved precisely to a given spot. A laser beam-break can be detected by a sensor which can sound an alarm to warn the operator. A similar application for beam-break detection is to indicate security breaches in vaults and museums, and simple line projections (without alarm) can be used as warning indicators for hazardous areas. Finally, a big application is the use of line lasers as OEM components in various camera vision systems for surface profiling.

Laserglow Technologies offers a wide variety of alignment lasers that are used for these, and many similar industrial applications. To learn more, watch our demo video or see the detailed product listings

Reconstructing 3D Holographic Scenes in a One-Step Process

A joint study conducted by researchers at University of Antioquia (Colombia) and CONICET (Argentina) demonstrates how a complete 3D scene can be reconstructed in a single step using a simple protocol. This method overcomes the limitations imposed by optical setups where illuminating an entire scene is not possible- either due to the collective size of objects, or due to the different optical requirements for various surfaces. Laserglow's 532nm DPSS laser was used as a light source.

The basic principle behind this method is being able to register individual holograms of various objects and applying a spatial filtering technique to create a compound Fresnel hologram. This new hologram allows simultaneous reconstruction of all the objects in one step using the same recovery procedure, setup and calculations that were used to create a single hologram.

Digital holography is a well-known tool for experimental optical data processing. By using this tool, it is possible to record and process information of both 2D and 3D objects which can then be remotely reconstructed using an optical system. In the context of digital holography, multiplexing means adding several bits of processed information to create a more compact information carrying unit. Multiplexing is found to be the best option when multiple 3D objects and images are taken into account.

The researchers applied the concept of hologram multiplexing to get a single digital hologram containing the entire scene. When propagated at an adequate distance, the reconstruction quality was found to be much better than previous methods.

To learn more about the experimental setup and the detailed study behind this method, access the academic paper at: Science Direct Full Paper

World's First White Laser Invented - And What it means for Lighting & Internet

Researchers at the Arizona State University have demonstrated the world's first white laser which could become a mainstream light source and potential replacement to LEDs. It's also possible that white lasers can be modified to provide both same-room illumination and wireless communication. The technology, termed Li-Fi, is currently under development and is 10 times faster than Wi-Fi. With white lasers however, the speed of Li-Fi could be 10 to 100 times faster than existing LED-based Li-Fi.

So far, creating a white laser has been extremely difficult because white light is produced through a combination of different wavelengths in the visible spectrum. The researchers have now proven that semiconductor lasers are capable of emitting over the full visible color spectrum, thereby creating a sharp beam of white light. They created a nano-scale device with three parallel segments, each supporting laser action in one of three primary colors - red, blue and green. When the total field is collected, a white color emerges.

Semiconductors are used in the making of LEDs and lasers because they can emit light of a particular color when a voltage is applied to them. The color produced is dependent on their atomic properties. When the atomic properties are too different from each other, it becomes difficult to combine semiconductors into a single structure to produce white light. The team used nanotechnology to solve this problem.

Over a period of years, the researchers have been able to grow single units of semiconductor materials with a wide range of atomic properties that allows color-tunable lasing on a single substrate. Now with a combination of right alloy contents, they've been able to create a semiconductor capable of producing white light. To learn more, go to: Phys.org full article

Additional Resources:

The research was first submitted by Arizona State University to Nature Publications, and published in the journal 'Nature Nanotechnology' DOI: 10.1038/nnano.2015.149