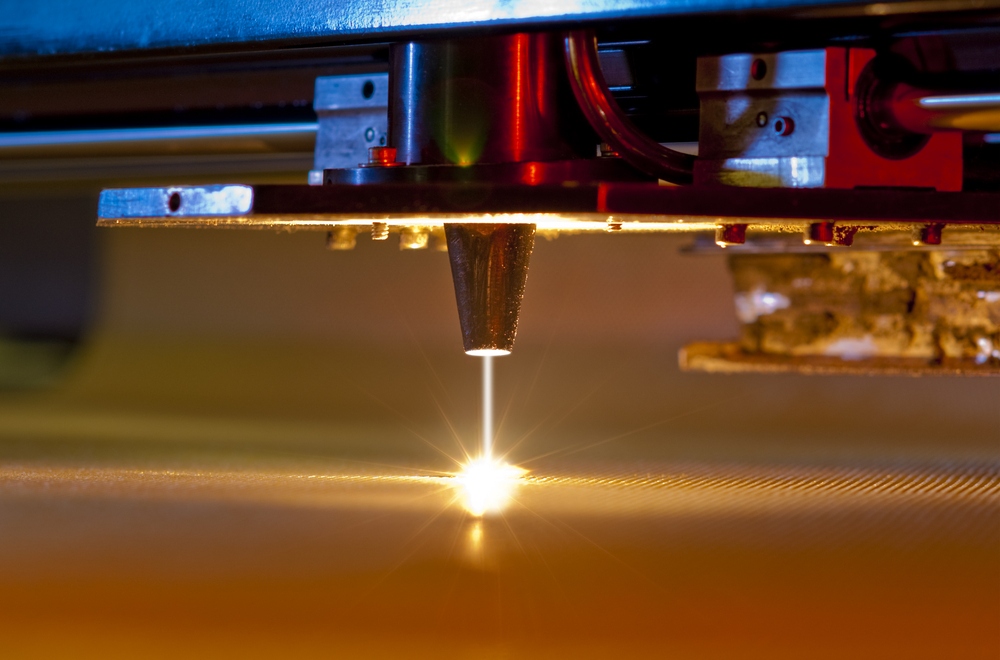

Materials Traceability and Parts Making - An integral component of ISO Quality Standard compliance is materials traceability. The performance of any materials traceability solutions relies on effective, reliable and visible data matrix codes or optical character recognition (OCR) characters. Laser marking is fundamentally different from ink printing, the traditional method of marking on materials. Direct ink printing puts an image on the surface of the plastic which can be removed by abrasion or solvents, but Laser marking can provide an indelible high-contrast mark in the material itself, with no direct contact with the material other than through the incident laser beam.

Laserglow provides complete selection of enclosed and OEM integrated lasers that we used for material marking. We understand that your needs are specific and have designed a comprehensive selection of lasers for all budgets and requirements. Our staff is experienced in recommending the ideal marking system for your application.

Materials Traceability and Parts Making Lasers